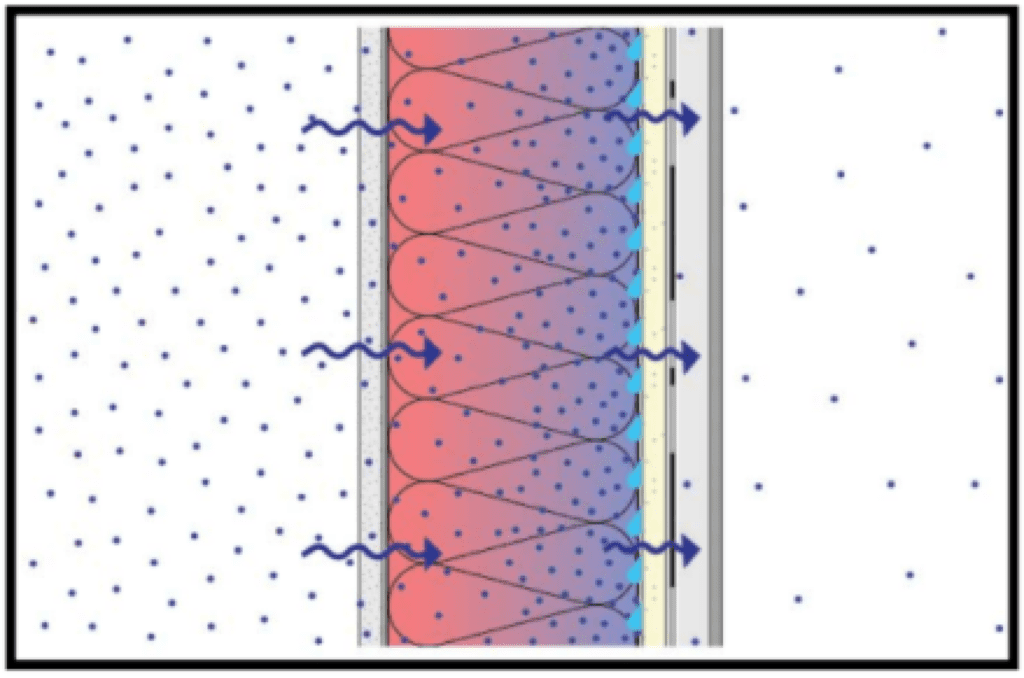

EIFS as a cladding system has been developed long

time ago hence is well researched and one of the

most tested cladding systems in the construction

industry, making it widely accepted, used and best

performing cladding systems when it come to

thermal and moisture control.

EIFS is also recognized as a system that is in full

compliance with modern building with greater

emphasis on energy conservation.

Needs to be applied by a trained and certified professional

Made from Portland cement – A Green House Gas

intensive material

Improper installation can lead to failures

Failure to allow curing time for inner layers can be

detrimental

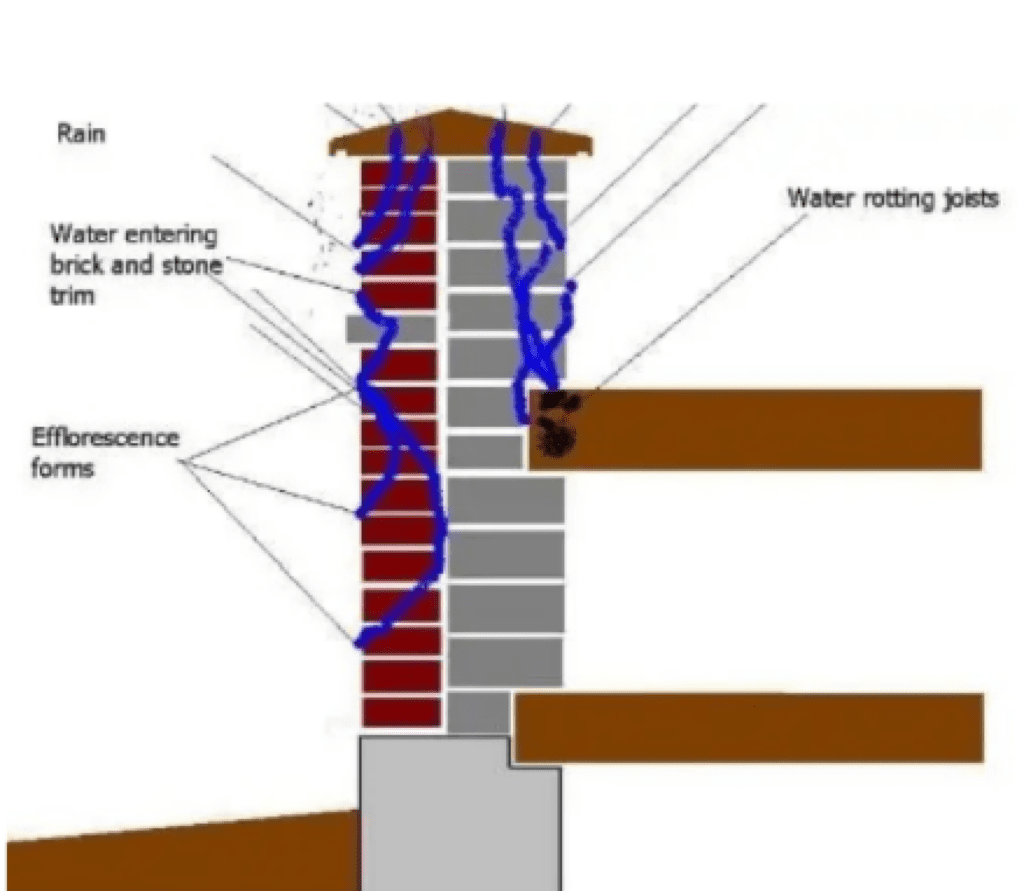

Stucco (the final finish / Top coat) will shrink over

time and crack, just like concrete.

It is porous and hence fails to keep the rain out in

case of prolonged exposure to rain.

The water leakage can find its way into the wooden

structure inside and cause mold and rot.

The synthetic acrylic polymer based top coats are

designed to be completely waterproof and do not

breathe at all, which means if the water finds its way

behind the top layers, it won’t have any way to

escape, unless it can weep out from the bottom of

the wall.

Calls for additional attention to the windows and

doors with high quality caulking and proper flashing.

Water can get trapped behind the synthetic stucco

systems.

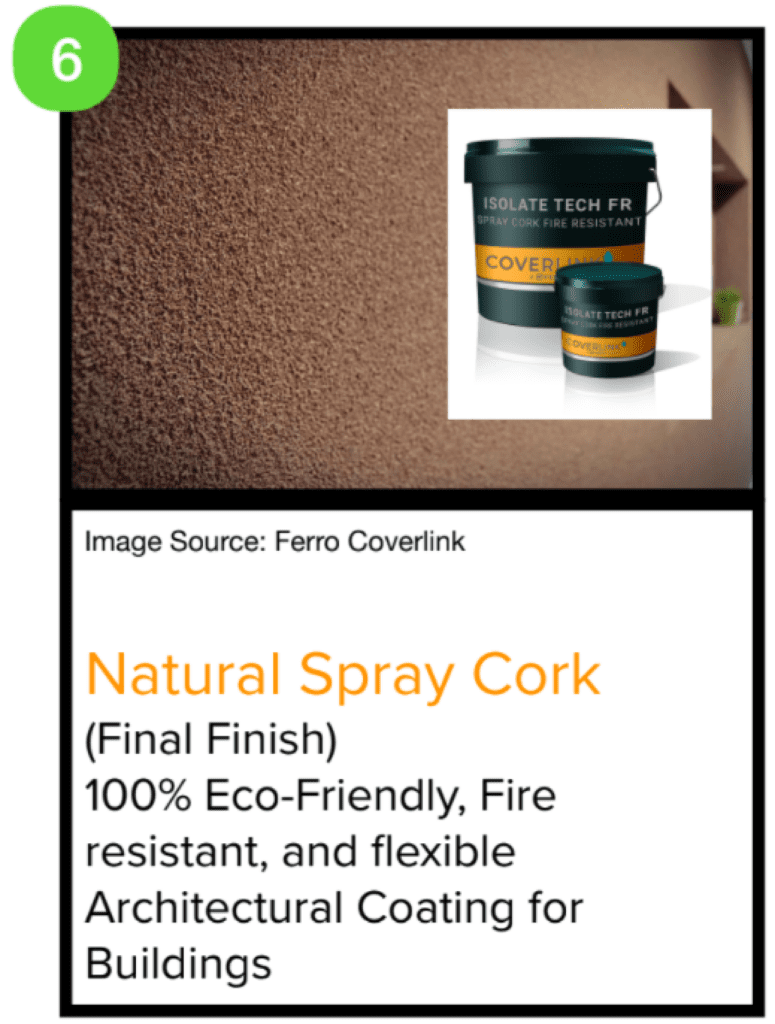

9) Be durable – Cork Spray is at least twice as

durable as the stucco. Currently Coverlink’s

Cork spray offers 10 years warranty, however

soon the warranty will be bumped up by additional 5 more years.

10) Be aesthetically pleasing – Aesthetics play an

important role in the final finish of the building.

Cork Spray being able to withstand all the forces

of nature much better than stucco will as a result

offer a long lease to the aesthetics of your

building. It also comes in choice of many

colours and the options are unlimited.

One of the important features offered by Cork Spray

is its resistance to Salt penetration. This property is not required by the Building Codes for exterior

walls, however it is important to note that all the

popular siding materials including stucco are less

resistant to salt than Spray Cork.